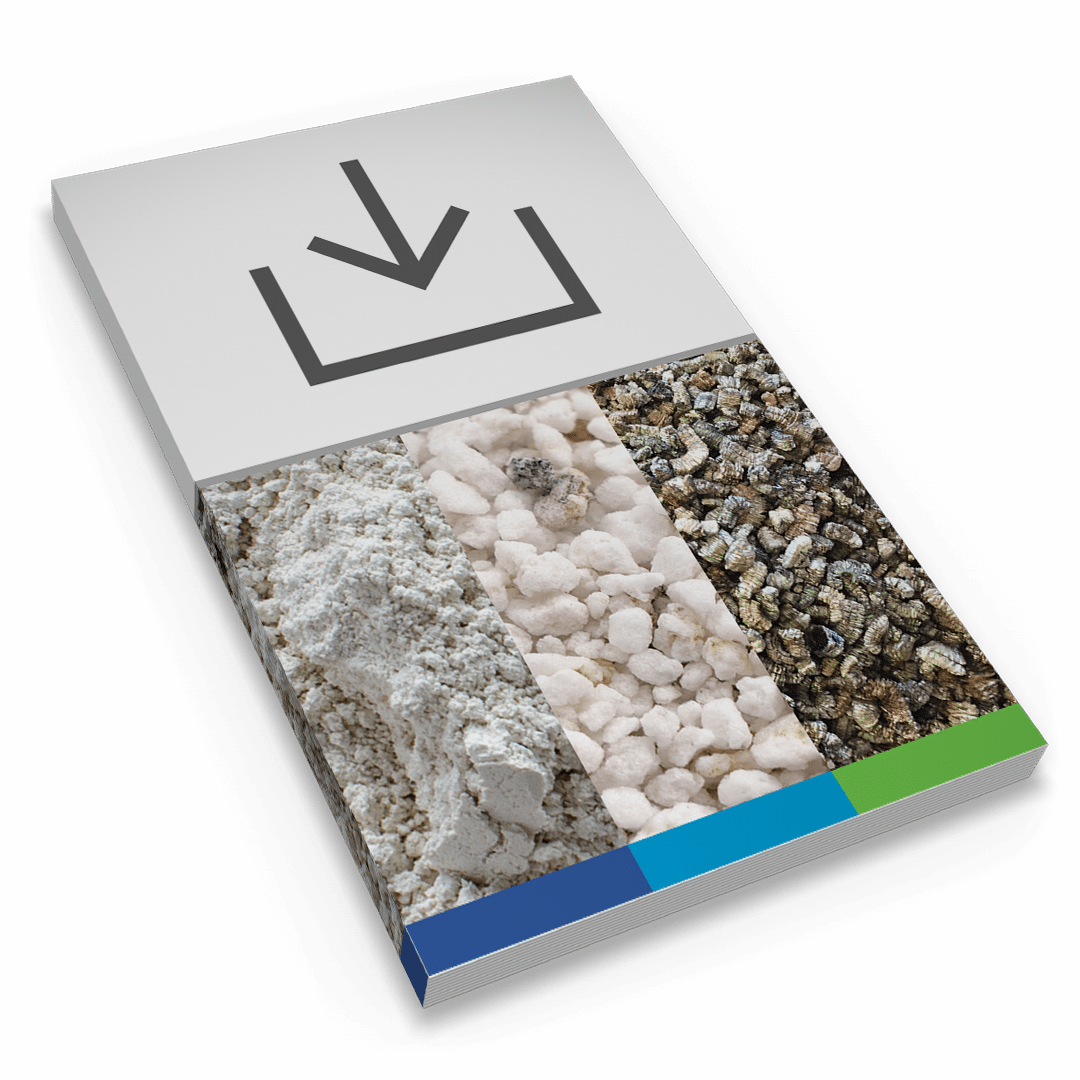

Perlite Ore

Our perlite deposit in Socorro, New Mexico has reserves of over 10,000,000 tons and is considered one of the deepest known commercial perlite deposits in the world. Dicalite is vertically integrated, meaning we own and operate both the perlite ore mine and expansion facilities which allow us to maintain a high level of quality control.

Perlite ore is formed by magmatic processes, and water is entrapped in the perlite matrix over time. These microscopic pockets of water give perlite ore it’s unique ability to “pop” under proper high-temperature conditions.

The chemical framework of our industry-leading Socorro perlite ore is amorphous, rather than crystallineas found in other industrial minerals. In its unprocessed state, it is usually light gray in color.

Benefits and Applications of Perlite Ore

The expansion and insulating properties of perlite ore make it suitable for use in high-temperature applications, particularly in the steel and foundry industries.

Hot Topping and Reisering

When mixed with exothermic powders, it can prevent shrinkage cavities in ingots and casting. It is most often used as a lightweight filler for these applications because of its availability, cost, and admirable properties.

Ladle Topping

Expanded or unexpanded granular ore forms of perlite are added to molten metal pouring ladles to cleanse the metal by coagulating impurities. The ore doesn’t smoke and no fumes are produced.

Foundry Core and Molding Sand

Perlite ore is used as a cushioning agent to compensate for the expansion of crystalline silica. It minimizes casting defects, and cleaning room costs are reduced.

Refractories

It is used in the manufacture of refractories where the average temperature does not exceed approximately 2000°F. If it exceeds this temperature, perlite is used as a backup insulating layer.

Perlite Ore Products and Applications

| Product TDS | Production Facility | Application |

|---|---|---|

| SOC79 | Socorro, NM | Horticulture, Foundry (slag coagulant) |

| SOC78 | Socorro, NM | Horticulture, Foundry (slag coagulant) |

| SOC77 | Socorro, NM | Horticulture, Foundry (slag coagulant) |

| SOC75 | Socorro, NM | Construction, horticulture, pet care, foundry |

| SOC73 | Socorro, NM | Construction, horticulture, pet care, foundry |

| SOC72 | Socorro, NM | Construction, horticulture, foundry |

| SOC71 | Socorro, NM | Construction, foundry |

| SOC69 | Socorro, NM | Construction, foundry |

| SOC68 | Socorro, NM | Construction |

| SOC67G | Socorro, NM | Construction, building products (ceiling tiles) |

| SOC67 | Socorro, NM | Construction, building products (ceiling tiles) |

| SOC66A | Socorro, NM | Construction, building products (ceiling tiles) |

| SOC66B | Socorro, NM | Construction, building products (ceiling tiles) , cryogenic insulation, filteraid |

| SOC66C | Socorro, NM | Construction, building products (ceiling tiles) , cryogenic insulation, filteraid |

| SOC66 | Socorro, NM | Construction, building products (ceiling tiles) , cryogenic insulation, filteraid |

| SOC63 | Socorro, NM | Filteraid |

| SOC60 | Socorro, NM | Supplementary cementitious material (natural pozzolan) |

Quality and Consistency—The Dicaperl Difference

Our Socorro deposit location has proven reserves of over 10,000,000 tons and is believed to be the deepest known commercial perlite deposit in the world. These characteristics give the expanded and processed Socorro ore unmatched quality and consistency.

In addition, we own and operate both the perlite ore mining locations and the processing and expansion facilities, allowing us to maintain a much higher level of quality control and ensuring volume and supply for our expanded perlite customers.

Contact Us

Contact us today to learn how we can help your processes, buy direct or from a distributor, or request a free sample of our products. We look forward to hearing from you.