Our Environmental Responsibility

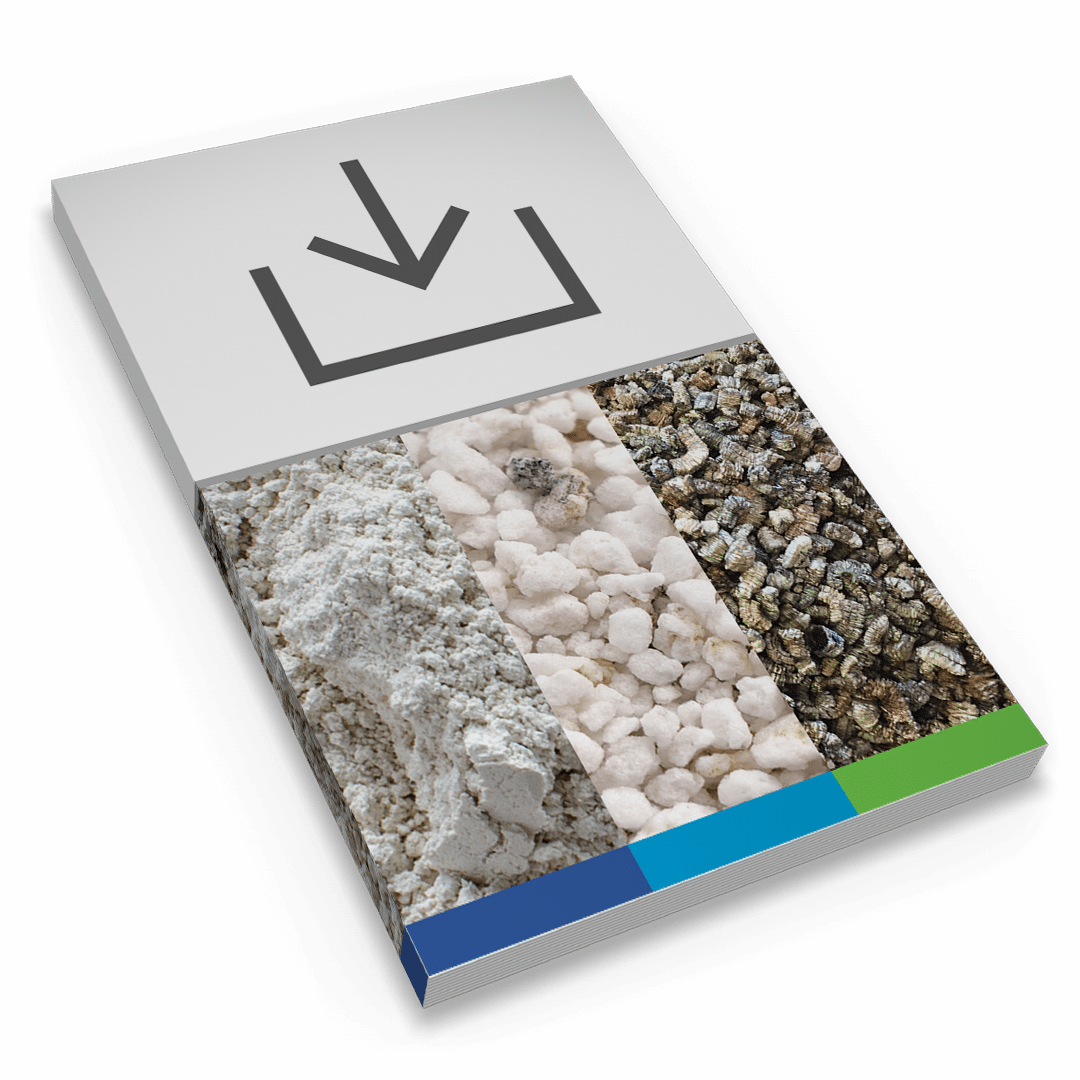

We mine and process our minerals in an environmentally friendly way.

Dicalite Management Group selectively surface mines the diatomite from our deposits. Care is given to minimize the amount of surface exposed during the process.

All our mining processes culminate with the reclamation of the disturbed areas of our mines. The diatomaceous earth makes an excellent growing medium and we replant native vegetation with the approval of environmental regulators to generate new (sometimes forested) ecosystems, within 10 years or less. Well over 2,000 trees are planted every year in active reclamation areas. These include local species of pines, firs, Incense Cedar, and oaks.

Dust Control

Dust is controlled in the quarries by water trucks and water wagons on a scheduled and recorded basis. Reclaimed water from mine runoff and stormwater is used whenever possible to reduce valuable water resources. Permanent roads are treated to further reduce dust.

Emissions

To protect the air quality and atmosphere, the air emissions from the processes are closely monitored and regulated. Several gases and particulates are controlled to ensure compliance with operating permitted levels. A baghouse is used to collect dust from the process air before the clean air is released into the atmosphere.

Rainfall-Runoff

Rainfall-runoff in the plant and quarries is controlled in many ways. Abandoned areas are revegetated to promote water retention. Where rain runoff occurs, slopes are engineered to reduce erosion. As a final check, all runoff is collected in siltation ponds to collect any debris or suspended material. Runoff may be used for dust control as described above. From these ponds, the runoff water is treated, settled again, and discharged to the local water sources in strict accordance Water Quality Permit standards.