MicroLite

MicroLite water-based fire-resistant coatings are a family of patented products that provide a safe, environmentally friendly method of improving the heat and fire resistance of textiles.

We are North America’s only producer of vermiculite dispersions. We offer a wide variety of viscosities and solids. Our MicroLite Vermiculite Dispersions can be applied to a variety of industries and applications from packing materials to fire resistance.

Available for use in:

- Aircraft paneling

- Barrier coatings on films

- Fiberglass textiles

- Fire-resistant fabrics

- Gaskets

- Packing materials

- Sound deadening insulation

- Thermal insulation

Benefits of MicroLite

- Enhances the sealability of products such as gaskets or packing materials

- Highly customizable and can be tailored to your needs

- Imparts fire resistance to products

- Limits gas exchange in plastic packaging

- Offers a high temperature coating, binder, or filler in various applications

MicroLite Products and Applications

| Product SDS | Production Facility | Applications |

|---|---|---|

| Formulated MicroLite Dispersions | Enoree, SC | Textile coatings, high temperature applications |

| Unformulated MicroLite Dispersions | Enoree, SC | Films and coatings for moisture and gas barrier applications |

| MicroLite Powder | Enoree, SC | Thickening agent for MicroLite dispersions |

How MicroLite is Produced

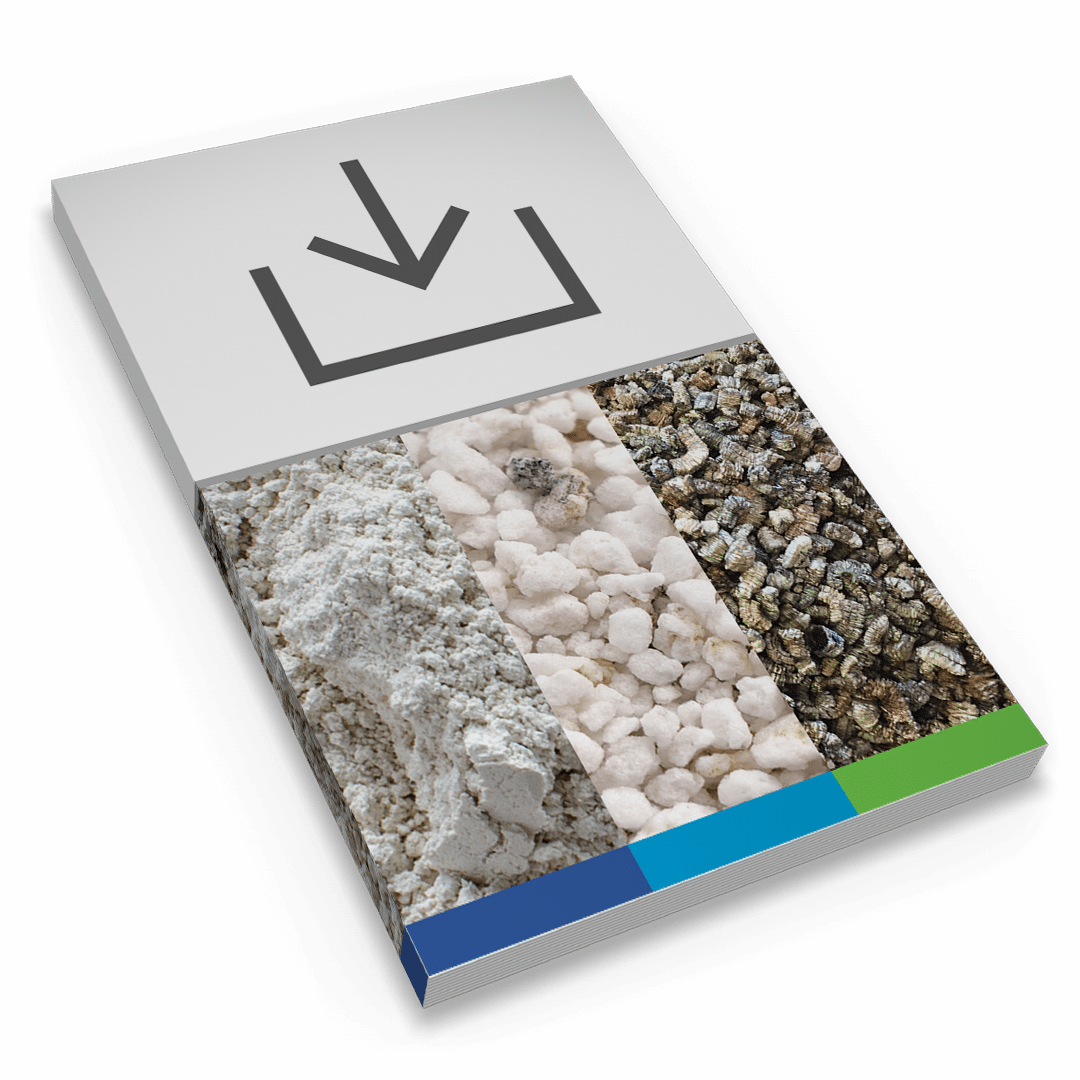

MicroLite is the chemical exfoliation of vermiculite. It is available as both a free-flowing dry powder and as aqueous colloidal dispersions. The vermiculite dispersions fall into two categories: unformulated and formulated products.

Free-Flowing Dry Powder

MicroLite powder consists of inorganic, high aspect ratio vermiculite platelets formed by the chemical exfoliation of vermiculite.

Formulated Dispersions

The formulated dispersions possess most of the same benefits outlined by the unformulated dispersions, and also include additives to provide improved performance in areas such as adhesion, flexibility, and/or color and dyeability.

Unformulated Dispersions

The unformulated products consist only of vermiculite and water. They are highly heat-and flame-resistant and produce virtually no off-gassing or smoke. In addition, these products are salt-free, and therefore are ideal for use in end products where corrosion is a concern.

Contact Us

Contact us today to learn how we can help your processes, buy direct or from a distributor, or request a free sample of our products. We look forward to hearing from you.