The Importance of Gas Barriers in Food Packaging

How MicroLite Vermiculite Dispersions Are Used

Gas barriers are widely used in packaging materials to prevent contact between the contents of a package and contaminates like gasses, odors, and pollution. Improving barrier properties is an important goal for manufacturers of films used for products such as foods, cosmetics, agricultural chemicals, and pharmaceuticals. Today we are going to look at the importance of gas barriers in food packaging.

The most common chemicals and compounds targeted for keeping out of packaging are oxygen, carbon dioxide, water vapor, aromatic hydrocarbons, residue, odor, flavors, smoke, environmental contaminates and more. Gas barriers are intended to maintain the quality of the product. Purposes include:

- Keep gas inside the package

- Keep moisture in the package to prevent the contents from dehydrating

- Prevent moisture from entering the package

- Keep perfume or flavor inside the packaging

- Keep undesirable odors or flavors from entering or leaving the packaging

Options for Gas Barriers in Food Packaging

Glass containers, metal cans, laminated products lined with aluminum, and plastics can provide a proper barrier to oxygen and other contaminants. Some differences exist between the various packaging systems, and the options are evaluated with these in mind:

- Permeability of gasses (like O2, CO2, and N2)

- Water vapor

- Aroma compounds

- Light permeability

Metals

Metals like tinplate and aluminum are some of the longest-term solutions for packaging foods. This type of packaging prevents microbes, light, and oxygen from affecting the products inside. The downfall is that metal is prone to corrosion.

Glass

Glass has high barrier properties, especially when preserving the aroma and taste of its contents. It is a popular choice because it is inert and nontoxic. A big concern is that transparent glass is visible to light, and light-sensitive contents should be stored in colored glass. Also, if it is not closed properly, it may compromise the barrier.

Laminates

Laminates feature multiple layers of foil, paper, plastic, or a mixture of multiple materials. When combining materials, the manufacturer can obtain more strength and barrier protection than using a single element. For example, laminates made of paper, foil, or polyethylene must have a plastic layer for heat sealing to create a leak-free container.

Plastic

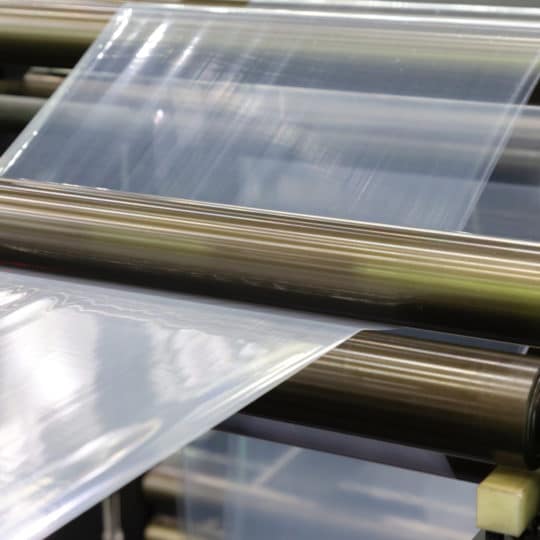

Plastic packaging is increasingly replacing traditional barrier methods because of its flexibility, variability, thermal stability, and barrier properties. Plus, plastic tends to be less expensive than metal and glass. Unlike metal or glass, however, there is great variation in its permeability, dependent on crystallinity, molecular orientation, chain stiffness, free volume, cohesive energy density, and more. Permeate properties—like molecule size and nature—and external conditions also cause differences.

Plastic is not a particularly effective gas barrier on its own. There are many methods that are used to improve the barrier properties of plastic, like biaxial orientation processes. It results in increase toughness, stiffness, clarity, and oil and grease resistance. It is often used for plastics like polypropylene, polyethylene terephthalate, and polyamide.

Additives to Enhance Performance of Gas Barriers

There are multiple ways gas barriers can be improved, including:

- Clay particles

- Nano-particles, like clay

- Specialty Vermiculite’s unformulated MicroLite

Why MicroLite Unformulated Vermiculite Dispersions for Gas Barriers

Specialty Vermiculite’s unformulated MicroLite is simply vermiculite and deionized water. This water-based vermiculite dispersion is used to coat flexible packaging films. The high aspect ratio platelets are ideal in the formulation of nanosized layers, forming a tortuous path barrier for gases like oxygen. MicroLite’s existence in this application can create 100 to 1,000 times improvement in gas barriers. This is imperative for common films like polyethylene plastic, polypropylene film, polyester, and polyethylene terephthalate, which have poor gas barrier properties.

One of Microlite’s benefits is that it has a clearly defined positive and negative electrostatic charges on surfaces and edges. This method can help singularize the platelet layers, which is especially important for film packaging and coating manufacturers.

MicroLite’s Many Opportunities

Our MicroLite is produced by the chemical exfoliation of vermiculite. It is available as both a free-flowing dry powder and as aqueous colloidal dispersions. The vermiculite dispersions fall into two broad categories: unformulated and formulated products. The unformulated products consist only of vermiculite and water. They are highly heat- and flame-resistant and produce virtually no off-gassing or smoke. In addition, these products are salt-free, and therefore are ideal for use in end products where corrosion is a concern.

MicroLite is a colloidal dispersion produced by chemical exfoliation. The vermiculite is separated into platelets with an average diameter of 25 microns with an aspect ratio of 400:1 or greater. In the best case, individual platelets can be produced with a thickness of as little as 1 nm and an aspect ratio of 25,000:1!

Request Your Free Sample of MicroLite.

For more information on MicroLite, visit our product finder or contact Commercial Sales at Specialty Vermiculite today to find out how our vermiculite dispersions can work for your food packaging products. Our sales and technical services team work closely together to ensure you get the best product for your application. We’ll also send you a free sample to get you started. Call us at 866-728-3303, option 2.

Join Our Mailing List

Our blog offers insight and information about new and exciting uses for perlite, diatomaceous earth, and vermiculite deriving from years of research and application. From passive fire resistance to mineral depth filtration, by subscribing to our mailing list, you will receive the latest information surrounding the Dicalite, Dicaperl, and Specialty Vermiculite brands and products.