Stay Warm Year-Round with Perlite in High-Temperature Insulation

As our calendars are nearing the start of springtime, many of us are starting to wish the temperature would rise a little faster. However, you don’t need the calendar to dictate the temperature in your home and beyond. You can stay warm year-round when you have the help of perlite in high-temperature insulation applications. With its light weight and naturally heat-resistant composition, perlite is valued as a superior high-temperature insulation product across many industries and for many consumer products. In fact, your home might utilize perlite to keep you warm—without you even knowing it. Learn about why it works, the different ways it’s used as high-temperature insulation, and why it’s a top choice.

Properties of Perlite

Perlite is one of nature’s most versatile and efficient minerals, it’s no surprise it is used for high-temperature insulation. This mineral is formed by magmatic rock, which you might know as volcanic glass. Over time, and during formation and cooling, water is absorbed into the raw perlite ore matrix, giving perlite its unique ability to expand when heated. These expanded perlite particles are lightweight and insulated glass bubbles that can hold water and air. In this state, perlite is revered for being:

- Lightweight

- Free of organic contaminants

- Pest-proof

- Insulating

- Fireproof

These insulating and fireproof properties make it an excellent choice for temperature-sensitive applications. Temperature limits include:

-

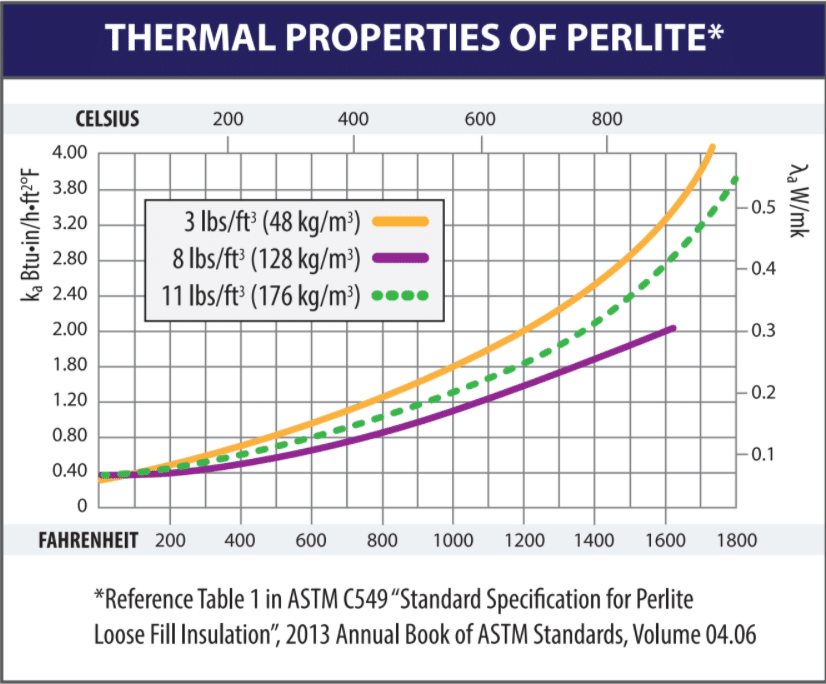

Thermal properties of perlite by The Perlite Institute

Softening point: 1,600-2,000 degrees Fahrenheit

- Fusion Point: 2,300-2,450 degrees Fahrenheit

Did you know perlite is also used in cryogenics? While this article goes over the high-temperature applications, perlite’s insulating properties also make it ideal for extremely low temperatures.

Perlite in High-Temperature Insulation by the Industry

Perlite is used across many industries to control and maintain temperature. It has many industrial applications and is used in the production of consumer goods.

Industrial

- Foundry: In the foundry industry, expanded perlite is most commonly mixed with exothermic powders. It is then used as an insulating cover on the surface of molten metal to prevent excessive heat loss during pouring delays, top off ingots, produce refractory blocks and brings, and act as a lightweight castable.

- Ladel topping: Perlite, either expanded or unexpanded, is added to the molten metal pouring ladle. The mineral reacts with slag in the ladle, allowing for easy removal of the layer. It does not produce smoke or dangerous fumes.

- Hot topping and risering: Perlite helps prevent shrinkage cavities in ingots and castings and is used as a lightweight filler. It is used in a range of 3% to 20% by weight.

- Gypsum wallboard: Perlite is used to create gypsum plaster, adding insulating properties while keeping it lighter in weight than its predecessor sand cement plaster.

Consumer Products

- Fireplace chimnies: Perlite is used as a fireplace chimney liner. This insulating perlite concrete keeps heat where it’s meant to be, preventing it from seeping through walls.

- Specialty stoves: As any chef knows, having a stable temperature for cooking is critical for success. Perlite is used as an insulator in specialty stoves like fuel-efficient rocket stoves and wood-fire pizza ovens to hold and stabilize the heat for predictable cooking.

- Concrete pool insulation: Perlite insulating concrete pool base can substantially reduce heat loss to the ground thus keeping pool water warmer for a longer swimming season. This will reduce energy costs when pool water is heated. In addition, the perlite pool base provides a firm, smooth, foundation that prolongs the life of vinyl liners.

Why Choose Perlite for Your High-Temperature Insulation

Energy Savings

Dicaperl’s masonry fill insulation has a unique closed-cell structure, which can drastically reduce heat transmission through masonry walls. Thanks to thermal performance tests, we know there are significant energy savings when perlite is used to fill cavities in concrete masonry structures. In fact, the tests determined that perlite masonry fill insulation can be more effective than polystyrene beads, foamed-in-place insulation, polystyrene inserts, polyurethane foam, and vermiculite core fill insulation.

Fills All Voids and Cavities

The key to perlite’s impressive performance is its flowability—the ability to completely fill all empty spaces in a masonry wall without the worry of bridging. This assures a completely and efficiently insulated wall. Plus, it enables a masonry contractor to install several courses of block before pouring insulation into cavities and holes. Perlite masonry fill insulation is non-settling and does not compact under its own weight, allowing it be permanent insulation that will last the lifetime of the structure.

Non-Combustible and Fire Ratings

Perlite is a Class A, Class 1 building material with a temperature range for fusion of 2,300 to 2,450 degrees Fahrenheit. Underwriters Laboratories show that a fire rating of a 2-hour rated 8, 10, or 12-inch concrete block wall is improved to 4-hours when cores are filled with masonry fill Tests show that a two-hour rated 8”, 10”, or 12” concrete block wall is improved to four hours when cores are filled with perlite masonry fill insulation. In addition, Dicaperl’s perlite insulation does not generate fumes when heated. These features of masonry fill insulation make the product particularly suitable for insulating stairwells and elevator shafts.

Easy Installation

As Dicaperl’s perlite masonry fill insulation is field-installed by following the layering of several courses of block. This ensures it does not interfere with the masonry contractor, nor is it subject to damage in handling. This fill insulation is simply poured into cores, ear holes, or cavities with a simple hopper. No special equipment or skills are required to properly insulate a masonry wall!

Stay Warm with High-Temperature Insulation Help from Dicalite Management Group.

Our multi-mineral offering of diatomaceous earth, perlite, and vermiculite ensures we have the right product for your application. The sales and technical services team at Dicalite Management Group work closely together to help meet your exact needs. Call us today at 866-728-3303 to get a free sample.

Did you know vermiculite can also be used in high-temperature applications? Vermiculite dispersions are inorganic and can be used to impart a high degree of fire protection in many industrial and construction applications. It can also upgrade the service temperature of the end product. You can also use our Product Finder to discover the minerals and products for specific applications.

Join Our Mailing List

Our blog offers insight and information about new and exciting uses for perlite, diatomaceous earth, and vermiculite deriving from years of research and application. From passive fire resistance to mineral depth filtration, by subscribing to our mailing list, you will receive the latest information surrounding the Dicalite, Dicaperl, and Specialty Vermiculite brands and products.